PART THREE

Baseboards.

Basingstoke

Mk1 was of course built in the loft of my German House. Its main constructional

disadvantage was the problem of the roof support beams, and even though the

available space appeared to be large enough to include Worting Junction and the

flyover, this proved impossible in practice. This was due to certain model

locos being incapable of pulling full length (12 car) trains up the realistic 1

in 90 gradients.

Basingstoke (Mk2) will have no roof supports to avoid, and with more space available will have gentler than real life gradients of 1 in 100 for Battledown flyover. Actual baseboard construction will follow the same methods I have used for over 30 years. For exhibition layouts I always use Marine Plywood, as this greatly resists warpage of baseboards. Baseboard warpage, especially at joins, is usually terminal, if you want to avoid derailments and other running problems....

Above: Basingstoke (Mk1). The fiddle yard baseboard under construction, back in 2010. The area seen here is about 22ft long.

As seen above the "Mk1" layout was built around the roof support beams. Being a fixed layout, the framework used 2.5" x 1.25" softwood, screwed to the roof support beams where available, to reduce the need for legs. Plywood being used primarily just for the baseboard tops.

As Basingstoke Mk2 is being built as a freestanding layout intended for exhibitions, it has to be built with regular length individual baseboards. These must be resistant not only to varying atmospheric and temperature changes, but the stresses of being humped around and loaded into and out of lorries. As a result each baseboard will use only Marine Plywood for its construction. 15mm thick plywood for the framework, which has to be at least 75mm (3"in) deep, to protect relays, point mechanisms and other electrical gear fitted under the baseboard top. The actual top will use 12mm plywood.

Each baseboard will then use carriage bolts and wingnuts to bolt it to its partner, and steel pattern makers aligning dowels to ensure precision alignment. This is critical if you want the tracks to align perfectly every time.

The baseboards will be supported by slot in legs around 1370mm (4ft 6in) high, to ensure viewers can see the trains and not just rooftops going around ! The slot in legs are held in place by blocks screwed inside each baseboard corner. To stop the layout rocking gently, the dual purpose "racking bars" used during transport, are bolted diagonally between each leg in a "W" pattern. As the layout is also an oblong in shape this ensures the layout when fully assembled is rigid.

To

cater for the problem of small children, I also build large sturdy wooden

"Kiddy boxes" with a handrail. This gives the kids a grandstand view,

ensures they have space amongst all the adults, and gives them something to

cling onto rather than the layout itself .

It´s pretty popular with Dad too !

Control panels and lighting pelmets are also bolted to the rear of the baseboards once assembled, although these will also have legs that reach the floor, to ensure baseboards don´t twist from their weight. All the methods so far described also ensure a relatively quick method of erecting and dismantling the layout. Something to be considered at large shows, where there is often chaos as many layouts, and their members struggle to get set up, or rush off home when the shows finished......

Above: An early view of the Mk1 layout. One corner needed removable baseboards to access a storage area. It shows my system of "slot in" legs, where the top crossbar of the leg doubles as a baseboard framework support, to help discourage sagging. (Summer 2010).

Once the baseboards are built and erected, the next step is to lay 5mm (1/8th") cork over the area where track will be laid. The cork is of course needed to remove the rumbling effect of trains, and makes running far smoother. It is necessary to use cork of at least 5mm thickness as the glue used to stick it down, and then stick the track to the cork is woodwork PVA. This glue is obviously absorbed slightly by the cork, so thin cork less than 5mm thickness is useless ! Cork wall tiles from the DIY store are usually the cheapest option.

Control Panels

Consideration

must also be given to the fundamental methods of operating large complex

layouts such as Basingstoke. It is by its nature beyond the capacity of even

two people to operate reliably or realistically. That is unless you want to

turn it into an automated train set. Which would totally defeat the reason for

building the layout in the first place. The idea being to get enjoyment out of

operating it, in as true and realistic a fashion as possible. This fact

therefore means that the track plan has to be divided up into sensible

operating areas.

As Basingstoke is basically a four track mainline, logically this means four mainline operators, each able to control one complete circuit. The two track Reading line with its own Fiddle Yard sidings, and its own goods yard at the station, makes two more operator positions. While the locomotive shed and the yards at that end of the station can be conveniently controlled by another operator. A seperate Fiddle Yard operator is needed to simply oversee loco and stock changes, and ensure trains don´t stop foul of pointwork.

Above: The Reading line panel on the Mk1 layout. On Mk2 the addition of Fiddle yard sidings and a second controller will be necessary, to this panel. Section power switches are white. Point control switches black. Signals switches Red. Communication switches Blue.

For

all this you need control panels with all the relevant controls on them, to

allow each operator to control his “patch”. Each control panel is therefore

built in timber along the lines of a Signalbox panel, with a track plan and the

necessary switches positioned on the plan to control the track, points and

signals and certain other accessories. This type of control panel is the

simplest and easiest style for any operator to learn, as everything is visually

displayed and positioned in the relevant position on the plan, and it´s all

instantly to hand.

The

control panels are then either bolted to the layout as with Basingstoke Mk1,

(as seen in the pictures) or with Mk2 they will simply be bolted to the layout but also have a pair of legs to avoid the problems of the weight twisting the baseboards. Into the control panels, which all have a hinged facia, go the

naked transformers necessary to provide all the supplies for the various

accessories used to make the layout function. I always provide separate

transformers for each. This means that the 12v DC point motors don't make

the signals dim when operated for example, as each has its own supply.

Above: The Up Fast and Up Slow control panel for

two operators. Part complete, but the first colour light signal repeater LED's

(11 illuminated) are visible.

The Up Slow and Up Fast panel seen above, gives an idea of a dual panel for two operators. The two tracks are marked with coloured lines, while white lines indicate tracks outside their control. At the time of the photo some of the signals and their panel repeaters had been installed. The panel repeaters only show the red or green. Red when the corresponding signal is red, and green when another colour on the actual signal is displayed. The operator only needs to know if the signal is at danger or clear. At that time the panel was provided with two hand held controllers, seen hanging at each end of the panel. This was necessary as the operators needed to move about a bit to oversee uncoupling of locos when required.

Because the layout is large, the various control panels are positioned at suitable places around the layout. So that we avoid shouting and loosing concentration, communication where necessary between control panels and their operators, is provided by a couple of switches and LED´s. So for example when the "Down Fast" line operator has a loco to send to the Locoshed, he simply turns on a switch marked "Loco for shed", which illuminates an LED on the Locoshed panel marked "Loco from Down Fast". When the locoshed operator is ready to accept the loco offered, he simply turns on a switch marked "Send", and a corresponding LED on the Down Fast panel lights up "Send". The operators must also check that the route is set and the signals clear, before actually making the move.

Above: The Down Fast and Down Slow dual panel about 75% complete. This panel was around 1.5metres (5ft) long.

In addition to the signal repeaters on the control panels, and the communications system just explained. It must be explained that all mainline pointwork is electrically interlocked with the signals. This ensures that if operators forget to check the points along a route, any point not correctly set, locks the relevant signal at Danger. Further, if the Operator fails to notice his signals are red, and attempts to drive the train past the signal. It will be brought to a halt in many cases where there is a risk of damaging the models by crashing. This "safety feature" typical of a real railway, is very simple to install. It simply means you extend the "frog" area of the relevant point by about a foot, electrically.

Further operational convenience is provided by using "Cab Control". This being a feature which allows two or more operators to actually control the same piece of track. For example: An electric multiple unit (EMU) arrives from London in the Down Slow platform, and is obviously driven by the Down Slow operator. Once it has arrived, its next move is to head back to London by crossing over to the Up Slow track, operated by the Up Slow operator. When the move is ready to be made, the Down Slow operator simply switches his platform track section switches to the "Up Slow" operator, who drives it away. This does not prevent the Down Slow operator from driving another train somewhere else on his circuit at the same time. This system also ensures that real railway type safety is adhered too. As "cab control" ensures that only ONE operator at a time has control of any section of track, with the signals and points being interlocked to also ensure someone else doesn´t crash their train into the EMU as it crosses the 4 track mainline. All real life features, it should be noted that Digital Command Control (DCC) model layouts can´t benefit from !!!!!

Above: The Locomotive shed control panel, half complete. Note the 35 section switches in the shed area, each capable of holding a loco.

The Locomotive shed panel as seen above, is slightly different in a few ways, due to its nature. Firstly so that locomotives can be driven reliably at very slow speeds whilst shunting around the shed area. When they go to turn or get water or coal, a special controller was used. This being a KPC (Kent Panel Controls) innertia resistance controller, specially modified for the job. The Heljan Turntable controller can be seen positioned correctly on the track plan. The turntable it controls can just be seen at the top of the picture. Control is very smooth and jerk free. Installation requires a hole to be cut in the baseboard, and it happily marries up to the Peco finescale code 75 rail of the surrounding track.

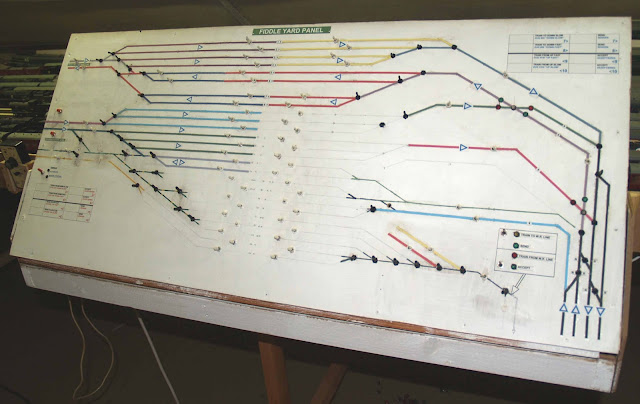

Above: The complex Fiddle Yard control panel, on the Mk1 layout, will no longer be needed on Mk2. The worst conflicting moves being the two diamond crossings seen at the right hand end of the plan.

On the Mk1 layout, the problem of not having Battledown Flyover, as a result of the inability of certain locos to climb the necessary gradient, meant conflicting movements in the Fiddle yard were also unavoidable. This required a control panel in the Fiddle Yard to oversee all moves in and out.

On Mk2 with the necessary flyovers now possible to remove conflicting moves, no Fiddle Yard panel is necessary. The 32 sidings in the new Fiddle Yard are divided amongst the six mainline control panels, so they each control their own storage tracks. This will also save on points, and point motors, as well as simplify operation in this large complex area.

Incidentally almost all the markings fixed to the control panel facias were simply printed off the computer, and cut out with a scalpel and steel rule, before being glued to the panel facia. The panels were then varnished on nearing completion.

That

currently completes "Operation and Control ". See also :-

Part 1 - Introduction

Part 2 - Further research

Part

4 - Coming soon.

Part 5 - Coming soon.

Part 6 - Coming soon.

Part

7 - Coming soon.

Links to other "Parts" below

Links to other "Parts" below

No comments:

Post a Comment

Comments and questions concerning the layout or the Railway Museum at Mora La Nova are welcome, but replies may take some time !