BASINGSTOKE IN "OO"

PART FIVE

Scenery and Structures

Above:

The scenery around Basingstoke, seen from the cab of a Battle of Britain

locomotive, as it passes over Battledown Flyover. Faintly visible on the

horizon is the town of Basingstoke. April 1967.

Much of the scenery is already pre-determined

when basing a layout on a real life location. This also of course involves all

the buildings and structures, and means that virtually all of these will have

to be scratchbuilt.

Above: Model scenery, including the local farmers cows....

A clear understanding of the scale of Basingstoke station can be obtained by refering to "Part One", where you will find scale plans of the station in the 1950´s.

Basingstoke station grew in stages. It began

with a two track line constructed by the London and South Western Railway

(LSWR). Then the Great Western Railway (GWR) arrived with a broad gauge single

track branch from Reading, and constructed a small terminus alongside the LSWR

station. The problems of trans-shipping goods between broad and standard gauge,

resulted in the GWR making their line dual gauge. It was also doubled as

business grew.

Growth affected the

LSWR as well, and the station was rebuilt first in 1861. Continued growth as

the LSWR network expanded resulted in the line from Waterloo to Worting

Junction, just to the South West of Basingstoke being quadrupled, around

1899/1900.

This resulted in a major rebuild at the

station as an extra two tracks had to be accommodated. So nearly all of the

1861 station was swept away and replaced, with completion of the new and much

enlarged station in 1910.

Above: Basingstoke station

soon after the reconstruction of 1910. The platform canopy next to the London

bound local train being about all that remained of the 1861 rebuild.

In 1935, the GWR

agreed to let the Southern Railway (SR) who had taken over from the LSWR, run

the complete station including the GWR part. This resulted in rationalisation

of the GWR part of the station. The GWR overall roof dating from the 1840´s was removed. The two GWR terminal

platform tracks were altered at the buffer stop end. They were linked together

to provide a run round loop, and this track was also extended to connect with

the SR locomotive shed, and SR Up freight sidings to the South. Only the GWR

platform forming an island with the SR Up Slow, continued as a passenger platform.

The other GWR platform simply becoming the run round loop, and a connecting

track for SR-GWR freight from the SR Up Yard.

Above:

All that remained of the ex GWR part of the station, seen in 1958. This shows

the normal passenger platform right. A railway special is using the normally

unused platform, run round loop. Although normally unused for passengers, this platform

had to remain in place as there was a station entrance and connecting subway.

When BR closed the

little GWR engine shed in 1950, the building was quickly demolished, and the

space used to expand the ex GWR goods yard (North Yard). By this time ex GWR

locos were mainly involved on Inter-regional workings and needed to use the SR

shed turntable as the ex GWR shed had no turntable.

Above:

Basingstoke station looking towards London, around 1962. This reveals the

station as it will be modelled. In the left background can be glimpsed the ex

GWR part of the station as seen in the previous photo. Virtually everything seen

here, except the platform lamps will have to be scratchbuilt.

Freight

at Basingstoke was catered for by goods yards provided by both the GWR and LSWR

primarily to serve the town and surrounding district. The GWR goods yard was

basically alongside its small terminal station, cut into the low hillside, on

the North side of the railway, and later named the North Yard. The Southern Goods Yard being positioned at

the opposite end of the station and on the opposite (Down side) of the line.

Both Goods Yards had large Goods shed buildings with two internal tracks.

Further

freight sidings were provided in the "V" between the junction of the

GWR and SR lines at the London end of the station and next to the line to

Reading. These were the original "Clearing House" sidings for

Interchange freight between the Two Railway Companies.

Yet further

the Southern found it necessary to install a handful of freight sidings on the

Up side of the mainline, which used basically the same access as locomotives

going to the locomotive shed. These sidings being opposite their main Downside

Goods Yard. These freight sidings became necessary post 1935 as a result of the

new freight and locomotive connection between the SR shed, and the ex GWR

station.

Above:

Having just departed the Up sidings South Yard, Class S15 4-6-0 No 30509

trundles through the Up Slow platform at Basingstoke with a trip freight for Woking

Yard.

Also

at the south western end of the station was the large Southern locomotive shed.

This being on the Up side, of the line and conveniently placed to allow ex GWR

engines direct access from the ex GWR part of the station, via the connection

installed around 1935.

Above: Devoid of name and number plates, Ex GWR 6851 "Hurst Grange"

4-6-0 simmers on the connecting line between the GWR part of the station and

the SR shed, seen in the background. August 1965

The pictures

above, clearly reveal much of the size of the station area, and many of the

structures to be modelled. Of course the scenery doesn´t stop here, as the

layout actually portrays a scale 5km of line. So much of the rolling

countryside, as seen in the initial picture at the top of the page, also has to

be made, including the flyover.

As I had transfered from 2mm Japanese outline modelling, when starting construction of Basingstoke. Changing scales involves a little re-coordination shall we say. So with respect to structural modelling in 4mm I decided to tackle something

fairly straightforward for starters. This being an industrial building or small

factory at the London end of the station. The building is actually fronting a

road that passes under the railway at this point. So little more than the roof

is visible at track level.

Above:

The first building tackled was this industrial building. The original also

visible in the magazine picture strategically placed, you might note !

Buildings

such as this, I make using plain white plasticard for the basic shell and

strength. Then Slaters embossed "brick" plastikard is overlayed. The

original roof during the period modelled appeared to change from corrugated asbestos

to asphalt matting. The latter being simpler to model was made by spraying a

sheet of A4 paper, in a subtle variety of deep grey shades. Then simply cut up

using a scalpel into strips, and glued to the plasticard roof. Items such as

downpipes, guttering and the chimney, were then added, made up from round, and

half round plastic rod. Other items such as bargeboards were cut to fit from

thin plastikard.

Above: An aerial shot of the Industrial building, revealing its full height and size. The road bridge and retaining wall also now added.

Next

I decided to model something more challenging and useful. So I turned my

attention to the Locomotive shed. Basingstoke shed was a three road structure.

At 170ft long it was obviously intended to accommodate a maximum of three

tender engines on each of the three roads. Something the size of Mr. Drummonds

quaint little T9 "Greyhound" 4-4-0´s for example.

Photos

of the shed in the 1960´s often reveal that three modern tender locos the size

of Mr. Bulleids rather larger West County Class, wouldn´t quite fit and spilled

out a little. This is rather inconvenient, as I wanted to get three

"bigun´s" inside. Mainly to keep the inevitable dust of as many locos

as possible, as much as possible. I therefore decided to build the shed

slightly over length at 200 feet, or a scale 800mm long in 1:76th scale.

Above:

The main shed "shell" in 3mm modellers plywood. A start having just

been made to cover this in Slaters plastikard "flemish bond"

brickwork.

In

addition to the length the actual shed area is also 56ft wide, and 40ft to the

roof hip. Further attached to one side are crewrooms and workshops making the

whole building even larger. The shed incidently had no roof windows, making it

rather dark inside. So I realised that sooner or later someone would derail a

locomotive by hitting the buffer stops inside the shed. Obviously the shed

would have to be removable to re-rail anything. I therefore decided the main

shed structure and the attached workshops would have to be built as two

separate structures. The "attached" workshops, would be fixed, and

also act as a guide when lifting off and replacing the main shed building. Even

so the actual shed part is still quite large, and fearing plasticard alone may

not be rigid enough, I decided to also use plywood. This being special

modellers plywood 3mm thick and intended for use in radio control aircraft or

boat construction.

Above:

The exterior being covered with "Slaters"

embossed plastikard brickwork. Interior sprayed matt black, the normal colour

inside any steam shed ! Roof construction just started.

The

ply was cut and glued together in up to three layers. So as to achieve the

buttress and other layered brick effects of the shed design. Once the shell was

constructed, and tested for strength and rigidity, Slaters "Flemish

bond" embossed plastikard was cut and glued to the wood. A start was then

made on the roof in 1mm plastikard. The original engine shed roof, appears from

most photos to have been made of something such as lead covered timber decking,

possibly also coated in Bitumen to ensure it didn´t leak. To replicate this

large "panelled" effect I simply cut up oblongs of 0.25mm thick

plasticard, and layed them like very large tiles over the supporting 1mm

plasticard. Then sprayed the whole roof in Halfords Matt black.

Above and below: The front and

rear of the model showing the awkward glass panelled areas in the apex of the

roof. Also the rear access door in green, and the blank section of walling

where the seperate workshops and crewrooms will butt up when constructed,

(upper photo).

The main roof chimneys were of metal construction, and

thankfully fairly simple to construct, as no complex brickwork or oddly shaped

chimney pots were involved. More complicated were the large glass panels at

each end of the shed in the apex of the roof. The one at the rear would appear

to have been repaired, possibly as a result of WW2 bomb damage, with fewer

panes. The front panel above the track entrances, always appears to have had

one or two broken panes, in various places. Probably as a result of locomotive

chimneys being parked directly beneath, and the heat cracking the glass. So the

model replicates this.

Above: The nearly complete main shed building, with

just the chimney tops to construct. The pits infront of the shed, are from the

"Peco" range.

One other point to note is the fact that the adjoining

workshops and crew rooms did not stretch for the whole length of the shed. But

only for two thirds. The final third of shed walling included a pair of large

double doors, I assume to allow locomotive parts to be dragged in and out on

trolleys. I should add that in addition to the workshops and crewrooms built

onto the side of the front two-thirds of the shed, there was a veritable

"village" of other small buildings and huts scattered around the rear

and between the shed and the mainline.

Above:

The rather run down real shed on 30.4.66, with a selection of BR Standard Class

4 and 5 locos. Class 5 No:73171 seen left is displaying the headcode for

"Inter-regional" trains via Reading. Which was intentionally the same

as other regions express headcode. The Southern 6 position headcode system

denoted route, not class of train, as on other regions !

The next building to be tackled was a first

step in construction of the numerous and large buildings required for the

station and its immediate environs. The first of these being the oldest

structure still remaining, that of the canopy at the country end of the Up Slow

platform which dates from 1861 and the stations first rebuild. It doesn’t match

at all with the newer canopies (one of which it is connected too) that were

installed during the second rebuilding around 1900-10. This odd canopy has a

mix of brick and timber for a rear support wall with a rather low V shaped

canopy roof. The cast iron support columns are not centrally placed but nearer

to the support wall than the platform edge. The model uses a piece of hardboard

as the rear support wall with plasticard planking and embossed brick parts, and

a plasticard roof section, with brass tube dressed for the supports. The Ratio

SR style concrete platform lamp seen in the photo below, has a loudspeaker

hanging from its nearest bracket, if you look carefully !

Above: The odd 1861 era platform canopy being test fitted. In the

foreground is the GWR to SR connecting spur. The two under bridges with the

local roads which actually joined beneath the platforms, part constructed. In

the background an M7 0-4-4T in the Down Bay, with a kit built Pull-Push set. In

front of the train are the first brass support columns for the next section of

platform canopy.

To finish up

this section on scenery are a selection of shots taken "out in the

countryside". The first reveals the part built formation around Oakley

station. Which on the "Mk1" layout had to be incorrectly positioned on

the four track section for the problems stated in Part 1. However it does

reveal typical rolling countryside as found in this geographical area. The

scenic materials are mainly from "Woodland

Scenics" which are made not from coloured sawdust, like many cheap

scatter materials, but from ground foam which uses a colour fast dye to resist

the bleaching effects of the sun.

It

may be pertinent to point out here that all the Peco track used on the layout

is of course the new code 75 NEM system "finescale" track. This

fairly new "finescale" track system was of course designed to meet

the new refined tolerances of the NEM wheels as fitted to virtually all new

model trains for some years now. Simply put if you insist on using the old code

100 type track, with modern NEM fitted rolling stock, you will experience more

derailments than with the new "finescale" track.

If locos in

particular still derail, then its most likely the back to back measurment on

the loco wheels is either to narrow or wide. This problem is easily cured if

you buy and "NEM Back to Back gauge". You simply push it between the

wheels to check the wheels accuracy. If the gauge won´t go in, gently force it

in. If there is slop, then you have to carefully press the wheels together a

bit on the axle. You´ll be surprised just how many commercial models are

fractionally out when purchased, and how much better everything runs as a

result of this quick check....

Above: A view of a hillside under construction. The polystyrene having been glued in place earlier is now being sanded to shape using a surform, prior to being covered in newspaper (see text).

Above: The area seen in the previous picture now papered over, and part painted in brown earth colour.

Hillside construction is achieved fairly quickly

and cheaply by using scraps of old polystyrene packaging, easily cut with a

small saw and stuck in place using non waterproof PVA Woodwork adhesive. You can then sand

the polystyrene to exact shape, once it´s glued firmly. Then rip up some old

newspapers into strips and dunk the strips in a bowl of PVA (20%) and water

(80%) well stirred. Slap the newspaper over the polystyrene about 3 or 4 layers

thick and leave for 24 hours to dry. Paint with a cheap brown/earth coloured

water based paint. When that´s dry, you´re ready to apply the scatter

materials, again using the non waterproof PVA, smeared neat, in a thin

film, over the painted paper. Only spread small areas of PVA about 150mm x

150mm (6" x 6") at a time, as the glue loses its tackiness fairly

rapidly, because it forms a skin. The scatter material should also be gently

patted into the glue to ensure it makes a good contact.

Above: The rolling Hampshire countryside, under construction around Oakley station. Polystyrene leftovers ready to form the next section of hillside in the background. Much of the track has been given a spray of "Track colour".

Ballasting can be achieved in a similar manner to hill construction. I use two slightly different methods. One for plain track and another for pointwork. It should be said that ballasting is a long laborious job, but if you don´t get this job right, your track simply won´t look realistic.

Above: Ballasted track. Here a four track section of Peco "Finescale" track, complete with 3rd rail, soldered to tiny brass screws for strength, has been laboriously ballasted and spayed "Track colour". The chalk cutting uses "Plaster of Paris Bandage" (from a chemist).

An important tip when laying track, is NEVER pin, screw or nail the track down. Screws, pins, nails will cause little dips in the track, and upset the smooth running of trains. I simply glue the track in place using PVA woodwork adhesive. This is strong enough to hold the track until you get around to ballasting it. I use "Tracksettas" (aluminium track rulers), to get nice sweeping curves without odd kinks in it. Then using Peco N gauge track pins, I very carefully just tack the track in place. Driving the pins only part way in. These pins are of course removed, as soon as the glue has dried. This will be sufficient to stop even flexi-track from moving while the glue dries.

I should add that to remove the rumbling effect of trains, I lay all my track on 1/8th inch ( 5mm) thick cork WALL tiles or rolls of this material. (Not floor tiles they are too hard). Purchased from DIY stores. As the PVA glue soaks into the cork material slightly, you need at least 1/8th inch thick cork, or the glue makes it to hard to remove much, if any of the rumbling effect !

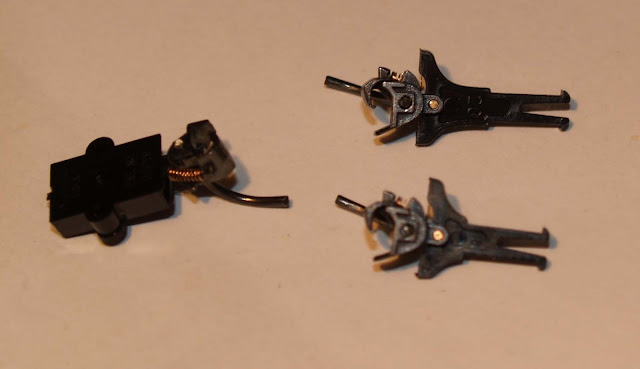

Above: Peco and handbuilt track laid on 5mm thick cork. Note that 5mm cork also helps provide depth for Kadee under track uncoupling magnets, one of which can be seen under the handbuilt track, this side of the steam locos driving wheels. The Peco third rail "pots" (white) were not strong enough being plastic, the 3rd rail being soldered instead to tiny brass nails. The locos (both modified Hornby) were testing 3rd rail clearances.

Firstly plain track. I carefully pour Woodland Scenics real granite fine (intended for N gauge) chippings onto a a section of track a couple of feet long. I then fiddle about smoothing it out so it reaches the top of the sleepers. If there is another track parallel I fill the complete space between the tracks to the top of the sleepers. On the track side next to scenery, the edge of the ballast needs to extend about 8-10mm beyond the sleeper ends. The full depth of the edge of the ballast should finish with a nice 45 degree bank, and this edge should stay neatly parallel with the track. Beyond the ballast on many sections of track was some sort of drainage ditch, particularly if the track was in a cutting.

I then spray the area from a few feet away with water using an old window cleaning liquid spray, to get the ballast damp. This helps to hold the ballast in place for the next step. Using an old Evo Stik PVA bottle, I fill this with only 15% PVA glue and 85% water, along with a couple of drops of Washing up liquid (to destroy surface tension). Give the bottle a good shake, before very carefully dripping this mix onto the fresh ballast.

Above: Plain track ballasting in progress, and a long 5ft/7ft curved handbuilt point at the end of Oakley station platforms.

With pointwork, because we don´t want to get ballast and glue into the moving parts if possible. I fill a jam jar half full with ballast, and then add the PVA/water/washing up liquid mix. Give this a good stir, and then carefully using a small old screwdriver (small enough to fit between the rails) apply little lumps of this ballast glue mix. Obviously the screwdriver acts as the applicator, and you can ensure the ballast only goes where needed and not around the moving tiebar, or other mechanism moving parts.

When the ballast is dry (usually a good 24hrs), it should be rock hard. You can then use something like "Railmatch Track Colour" spray paint, to cover the whole track area. Ensure all the rail sides are also covered. When this is dry you simply use a Peco track rubber or similar to rub the rail surfaces clean.

Above: More scenery. The A30 road, crossing both the Southampton and West of England lines on Basingstoke Mk1. Here the track, bridges, and cuttings are virtually finished, and a start had been made on constructing the railway cottages at this point. The King Alfred (of Winchester) buses, even have the right destination blinds - Basingstoke and Stockbridge.

One last and important point about my method is this. Having used the PVA non waterproof variant (In the green bottle if using Evo-stik). It is possible to lift your track, and replace, move or salvage it, should you need too. You simply pour warm water onto the track, and leave for about ten minutes to soak in. Then using a steel ruler you can carefully slide this under the track, and lift it. You can then wash the track, to get remaining bits of ballast off.

Above: A little detail. A speed sign for the junction, a signalling electrical cabinet, and some point motors of the type found around Basingstoke, and of course those telegraph poles.

Above: Oakley station car park area. Track and ballasting complete. Hillsides and platforms in place. Etched brass Scots Pine trees planted. Fences and hedges now being installed, as the tail of an Inter-regional train, Gresely & Thompson coaches, passes. Now wheres that station building got too....

The hedges seen in the photos were made from Woodland Scenics foliage material glued over some odd scraps of cork tile. The etched brass Scots Pines and other types of trees, are from an Architectural Company "3D" in London. Many of the trackside fences are made from fine brass wire and square plastic rod with holes carefully drilled through them. Even the dummy point motors were made out of plasticard, to the type seen around Basingstoke around 1960. The signals seen, are modified Eckon heads, on scratchbuilt (plasticard) gantries, or Model Signal Engineering (MSE) etched brass kit gantries.

That currently completes "Scenery and Structures". See also :-

Part 1 - Introduction.

Part 2 - Further Research.

Part 3 - Baseboards and Control Panels.

Part 4 - Construction and Operation.

Part 6 - Coming soon - Steam locomotives.

Part 7 - Coming soon - Modern Traction.

Part 8 - Coming soon - Coaching Stock.